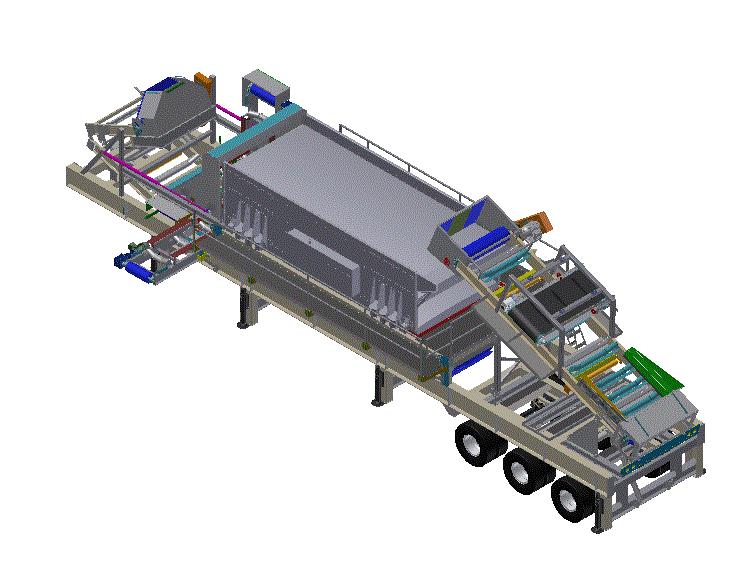

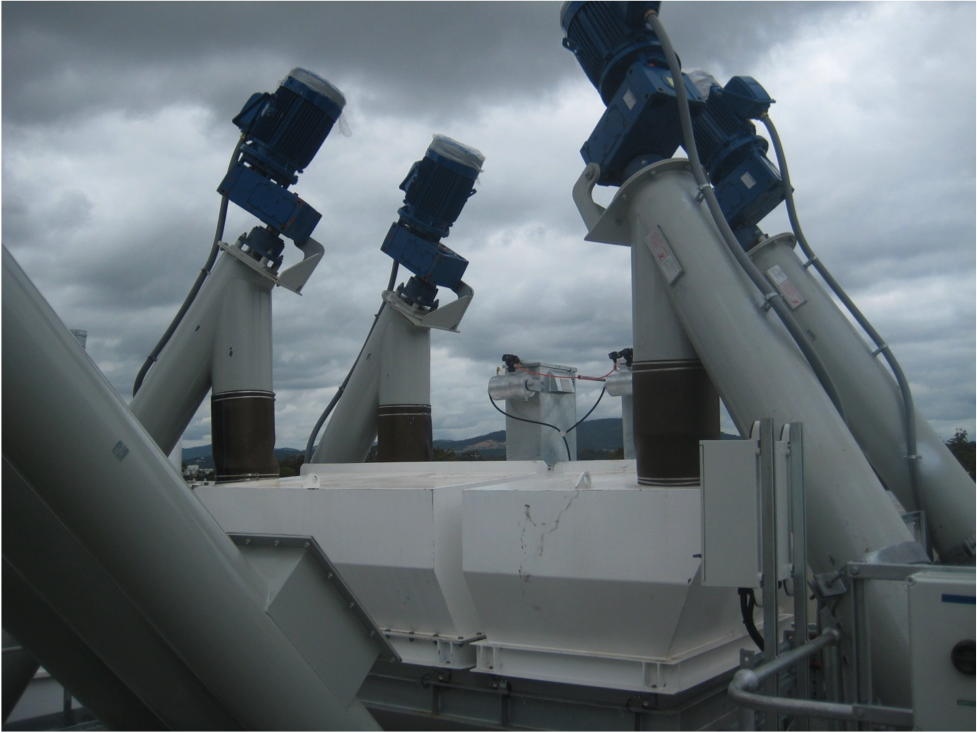

Dust control system of 30000 cfm for a batch plant capable of producing 600 cuyd/h.

-

Dust control system of 30000 cfm for a batch plant capable of producing 600 cuyd/h.

-

Concrete Mixers

-

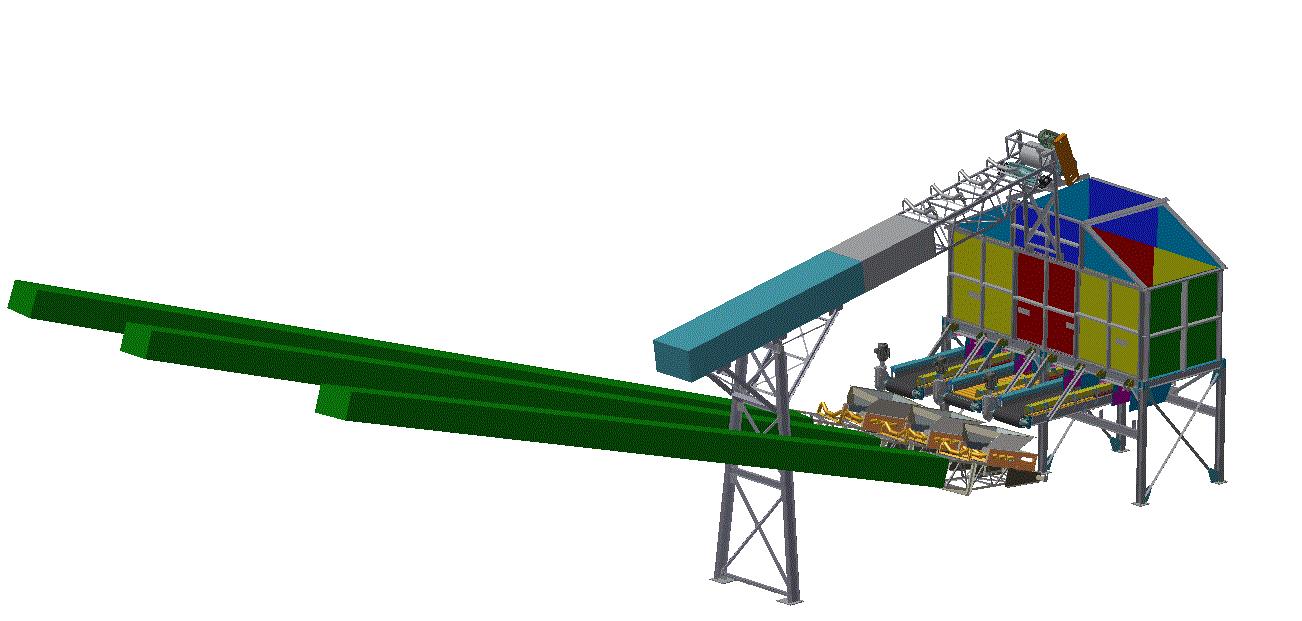

Batch plant layout and stocking project with traffic patterns, replenishing rates and 30 ton/day ice production facility that injects directly into the batch plant.

-

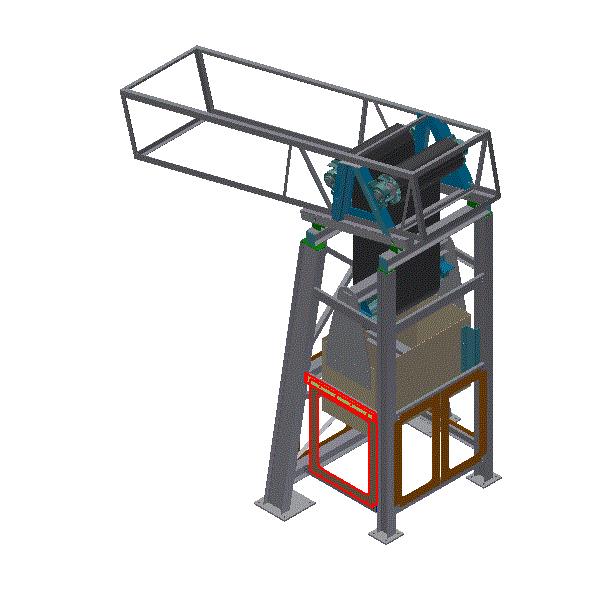

Gravity Take Ups

-

Construction management for two micropile foundations holding a 10,000 barrel silos on each foundation.

-

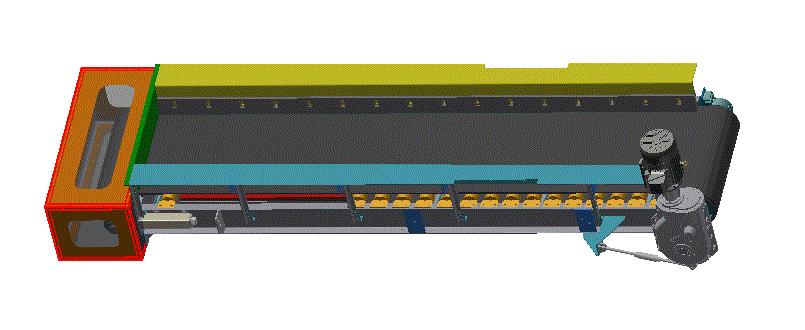

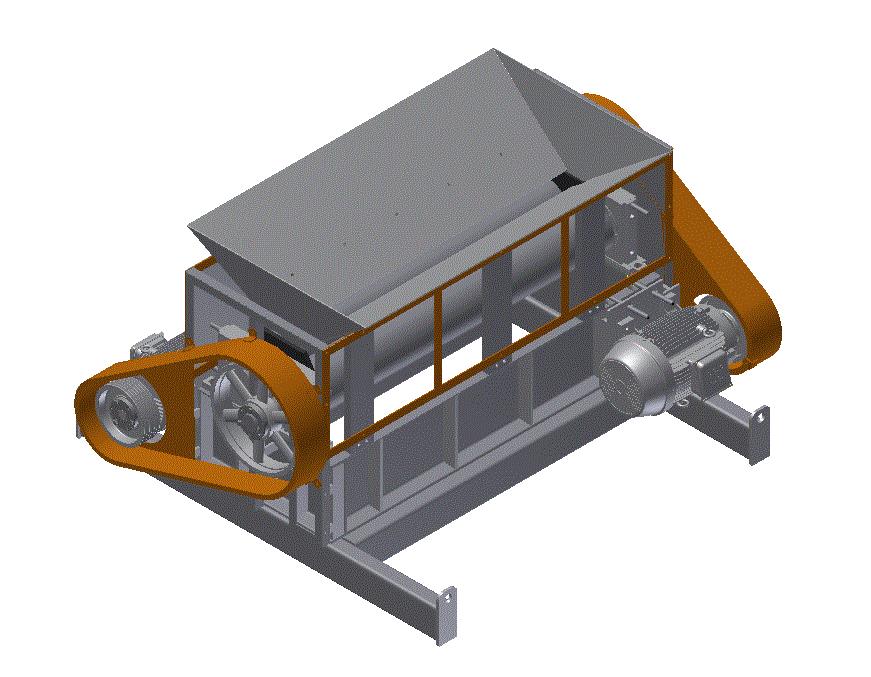

Conveyor Feeders

-

Construction management for a micropile foundation for a high production concrete batch plant built in location that other methods have caused shut-down for the operation. Plant was built with no shut-down days for the existing operation.

-

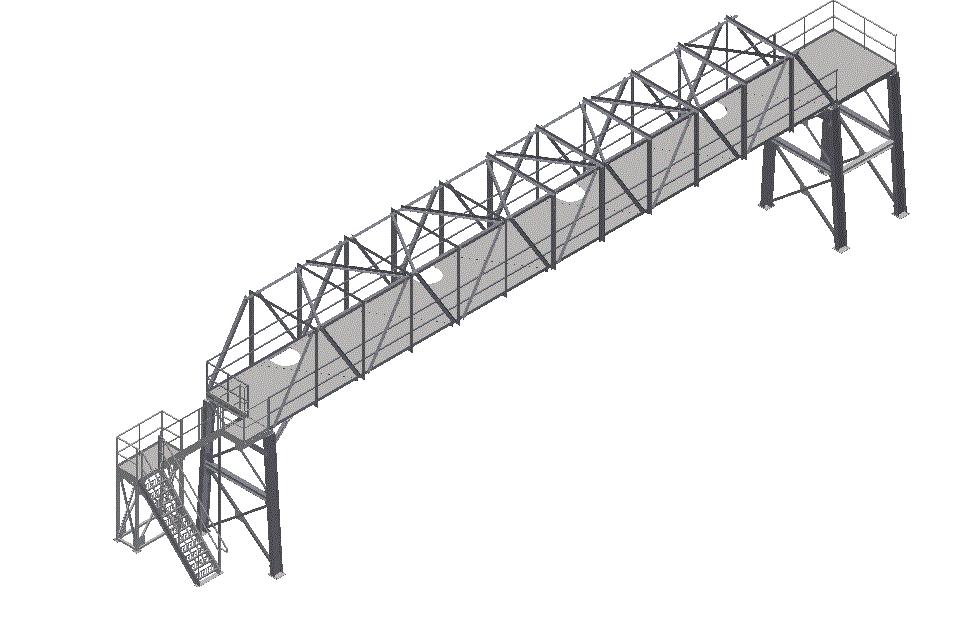

Conveyor Systems

-

Batch plant construction management Placing a second batch plant on top of the first one while the initial one is operational

-

Portable Screening Plant

-

Equipment designed to produce 60 tons/h of a mixture for placement in USGA greens. Included process design, equipment design, intelligent control and fabrication management.

-

Roll Crushers

-

Batch plants usually produce large volumes of water that need reclaiming. Settlement systems are used to reclaim the water, they are designed to be efficient, space savers, utilizing the layout of the site to their greatest advantage. Site should be capable of returning the water for reuse in a batching process.

-

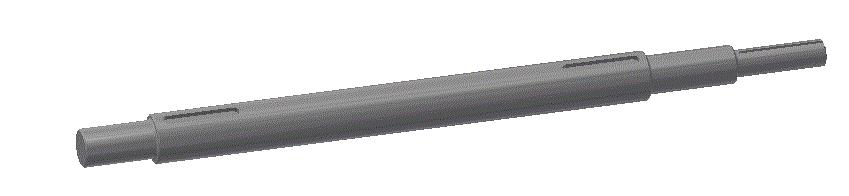

Shaft Design

-

Investigate 1960s building with structural damages to roof trusses. Made repairs as needed to bring the building to structural integrity.

-

Take Up Frame

-

Construction management for two micropile foundations holding a 10,000 barrel silos on each foundation.

-

Working Platforms

-

Engineer pneumatically controlled air systems and develop complete control valving, requirements to include storage and line sizing.

-

Engineer pneumatically controlled air systems and develop complete control valving, requirements to include storage and line sizing.

-

Application engineering applied to screw conveyors for cementitious materials and weight scale systems, to include weight scale design.

-

To develop the process of shrink batching with efficient current mixing technology allowing for complete mixing of the mortar components prior to loading the truck.